A question came into the office from one of our remote salespeople that peaked some interest. The customer had asked about damaged pallet rack. They are looking at reconfiguring their current warehouse space and during this time it will be easy to replace the damaged uprights. The client had requested information relating the amount of damage to a correlating reduction in capacity.

This created a bit of a problem on our end. The information he was seeking doesn’t really exist. As an example, a pallet rack upright can be damaged in a multitude of ways, and each way would affect capacity with differing magnitude. An impacted crease to an upright is different than torsion damage, for example. So, we went digging for a response.

We decided that the best course of action would be to reference the Rack Manufacturers Institute, part of the MHIA (Material Handling Industry of America). There are three really excellent points of reference in their FAQ’s.

1. What should I do if a rack upright column or other component is damaged?

The RMI Specification states, “Upon any visible damage, the pertinent portions of the rack shall be unloaded immediately by the user and the damaged portion shall be adequately repaired or replaced.” If the damage were to re-occur, the application of the racks should be reviewed to see if modifications could be made to lessen the severity or the frequency of the damage. Forklift driver training is essential.

2. What is an acceptable repair of a damaged rack component?

The detail used to make an acceptable repair should be designed or reviewed by a qualified design engineer and installed by people who are qualified to make the repair. The rack repair should be reviewed for compliance with the ANSI/RMI MH 16.1 Specification. A good repair will result in a structural member or connection that is at least as strong as the original.

When welding is prescribed, the welders must be certified for the types of welded joint required.

3. How far out-of-plumb can my rack be before I need to repair it?

The ANSI/RMI Specification shows the maximum out-of-plumb ratio for a loaded rack column as 1/2” per 10 feet of height. Columns whose out-of-plumb ratio exceeds this limit must be unloaded and re-plumbed. Any damaged parts must be repaired or replaced. This ratio could be used for straightness also. In other words, the out-of-straightness limit between any two points on a column should not exceed 0.05” per foot of length (1/2” per 10 feet).

An out-of-plumb or out-of-straight condition will reduce the capacity of a rack column. The reduction can be significant. A rack that is out-of-plumb from top to bottom or a rack column that is not straight is likely to become further out-of-plumb or out-of-straight when it is loaded.

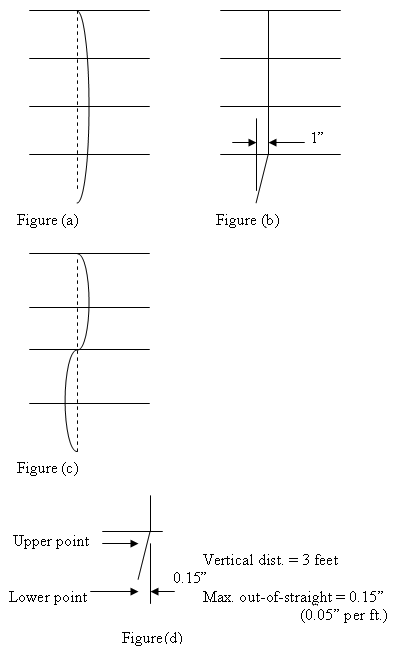

The out-of-straight limit is given to prevent excessive “bows” or “dogleg” conditions that may exist in a rack column. A column could be plumb from top to bottom but have an unacceptable bow at mid-height (see figure (a)), or a 20 foot high column could be out 1” from top to bottom, which could be acceptable using a simple top-to-bottom out-of-plumb measurement, but the entire out-of-plumb could be between the floor and the 5 ft. level (see figure (b)). This dogleg condition would be very harmful. This condition could be caused by fork truck impact. The column could have a sine wave shape and be out of straight as shown in figure(c). A column could also become bent and exceed this limit (see figure (d)). As re-written the specification now prevents these situations from being acceptable if they exceed the 0.05″ per foot out of straight limit.

This information is valuable. Damaged pallet racks are dangerous and the affected area should be unloaded immediately upon discovery. Our most common advice to our customers regarding repairing or replacing a damaged upright is typically to replace the upright. It’s cost prohibitive to repair an upright and keep in line with the ANSI RMI specifications.

This information is valuable. Damaged pallet racks are dangerous and the affected area should be unloaded immediately upon discovery. Our most common advice to our customers regarding repairing or replacing a damaged upright is typically to replace the upright. It’s cost prohibitive to repair an upright and keep in line with the ANSI RMI specifications.

If you have questions regarding your pallet rack, don’t hesitate to contact us.