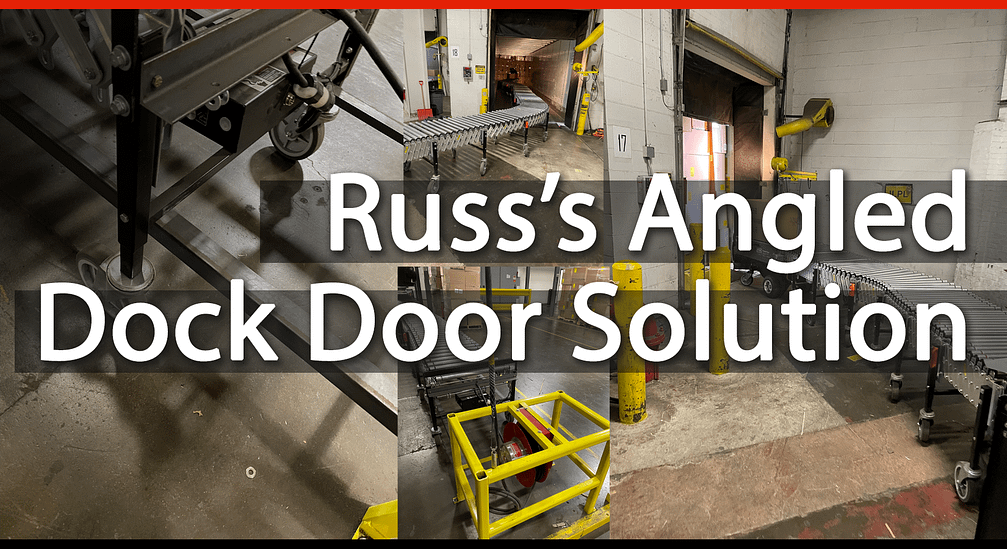

The Customer Had a Problem...

When Conveyer & Caster Account Manager Russ was approached by a prominent shoe design and distribution company for assistance in enhancing their loading and unloading process, he quickly learned of the difficulties presented by the customer’s angled dock doors. The sharp angle of these doors and the shape of the building’s walls around them, as well as the proximity of other dock doors, created a challenging task to improve the efficiency with standard conveyance equipment. The customer needed cost-effective powered conveyor solutions that were mobile and flexible to achieve their goals, while also maintaining a minimal equipment footprint. To overcome these issues, Russ couldn’t just use a straight, rigid conveyor – he needed to come up with a creative solution.

..and Russ had the Solution

With these details in mind, Russ set out to create the most effective solution for the customer with Conveyer & Caster’s technical and engineering teams. The team designed a conveyance solution that would not only achieve the customer’s goals in their existing space, but one that is designed to continue to perform for their high-volume needs, consisting of a set of 19 expanding and collapsing conveyers with onboard chargeable power units. Though there was additional competition, Russ and Conveyer & Caster were able to partner with the customer on the project and deliver the top-notch solution and service that the customer trusted prior to their purchase. Though their current products are rather lightweight in nature, Russ exceeded their minimal requirements supporting up to 150 kg/m, should they ever expand into heavier requirements or packaging. Additionally, the flexible and movable nature of the conveyors gave the shoe distributor a versatile option to move inventory not only onto and off trucks, but from any point in their warehouse to another without having to purchase additional system. This was done by Including an onboard power unit, which enabled mobility and flexibility.

Over a 16-week process, Conveyer & Caster was able to deliver all 19 conveyors and get them up and running for the distributor by January 2023. The customer was highly pleased with the results and is happily and efficiently conveying shoes on their brand-new powered conveyor system, despite the challenges of the angled dock doors.