Having worked in retail throughout high school and college, I spent a good amount of time around pallet racks in the stock rooms. I had no idea how many different kinds there were, and how important it was to choose the correct pallet racking until I attended MODEX earlier this year. Every corner I turned on, the exhibition floor seemed to have a different racking company around it — each with their own type of rack. Little did I know just how different each one was.

We’ve covered pallet racks in previous posts, but they traditionally come in the following systems, each with their own benefits: keystone, teardrop, structural, double-deep, push-back, pallet flow and drive-in. Once you’ve determined which is best for your needs, there are additional factors to keep in mind.

Space

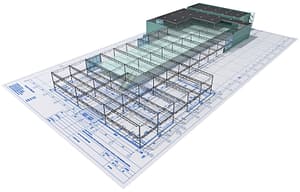

When starting with a pallet racking project, the first thing you need to do is measure the overall space you’re considering. This includes the total area of the floor as well as the height of the ceiling. Adding vertical storage will also increase the load on the floor, so make sure the floor can stand up to the added capacity.

Layout

Once you know the space you have to work with, you can start a general layout of your project. This will allow you to plan the orientation of the rack and aisles, and the space needed between racks and other obstructions. Common obstructions include light fixtures, support beams, doors and fire sprinkler systems.

Dimensions and Weight of Materials

Knowing the size, shape, and weight of what you’re planning to store will ensure that the rack will be sized appropriately and can stand up to the weight. If items are stored on pallets, you need to account for the space of the pallet, and proper clearance when adding pallets to the rack. Keeping these in mind will also help you choose the proper frame components.

How Material Will Be Added

Similarly to the materials’ dimensions, how the materials will be added to the rack is important to keep in mind. If you plan on adding and pulling things by hand, a smaller aisle can be used. If forklifts are needed, a wider aisle will be necessary for proper maneuverability of the lifts.

Decking

Adding wire decking will ensure items do not fall through the structure, while also providing additional support for pallets. Frame width and depth will need to be considered when selecting decking. Deck capacity is also calculated differently than frame capacity.

Other Accessories

Now that you have all of the major elements figured out, it’s time to add the bells and whistles. Local building codes may dictate the types of anchors needed to secure the racks to the floor and walls. Column guards will help prevent damage to critical support pieces from forklifts, pallet jacks and other vehicle traffic.

Lastly, consider if safety netting or rigid guards are needed at the back of the rack to prevent materials from shifting or falling off of the back of the rack, which could damage products, cause a spill, or cause injury.

Ready to kick off your project? Let our team of project managers and engineers work with you to design a pallet rack solution that fits your needs and available space.